-

MenuBack

-

Accessories

-

-

Battery Chargers

-

Bike To Bike Communication

-

Chain Lubes & Cleaners

-

-

-

Duct Tape

-

Fasteners & Bolt Kits

-

Foot Pegs

-

Fork Bleeders

-

Handlebar & Grips

-

-

Seat Pads & Covers

-

-

Stickers

-

Tank Caps & Breathers

-

-

-

Parts

-

-

Batteries

-

-

Chain Rollers

-

-

Cooling System

-

-

Fork Seals & Fork Bushes

-

Oil Filters

-

Spark Plugs & caps

-

-

Oils & Lubricants

-

-

Brake & Clutch

-

Chain Lubes and Cleaners

-

-

-

Engine & Gear Oils

-

Fork Oil

-

-

-

Motorcycle Care Products

-

-

-

Radiator Fluids

-

-

-

ELECTRICAL

-

-

Bike To Bike communication

-

Handlebar Switches

-

CDI & Rectifiers

-

-

-

Spark Plugs

-

Spark Plug Caps

-

Starter Motors

-

-

-

Hour Meter

-

Indicators Universal

-

Speedometers

-

Electrical Cables

-

-

-

Tyres & Wheels

-

-

Spokes

-

Tyre Repair

-

Wheel Balancers, Bead Breakers & Tyre Changers

-

-

-

-

-

Adventure Tyres

-

Off-Road Tyres

-

Road Tyres

-

Scooter Tyres

-

-

-

Helmets

-

-

Dual Purpose

-

Open Face

-

-

-

-

Car Helmets

-

-

Off Road

-

Accessories

-

-

-

Riding Gear

-

-

Body Protection

-

-

-

Casual Wear

-

-

-

Goggles

-

Hydration

-

Knee Sliders

-

-

Leg Bags

-

Socks

-

Neck Warmers & Face Masks

-

Race Suits

-

-

-

Brands

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Shop All Brands

-

-

-

Contact us

-

-

Trac-Mac Online

Tel: 021-917 1172 E-mail: sales@trac-mac.com

-

-

-

Trac-Mac Bellville

9 C/O Raglan & Aylesbury Street Bellville Tel: 021-945 3724

-

-

-

Trac-Mac Wynberg

33 Main Road Plumstead Tel: 021-557 5775

-

-

-

Trac-Mac Paarden Eiland

28 Marine Drive Paarden Eiland Tel: 021-510 2258

-

-

Search

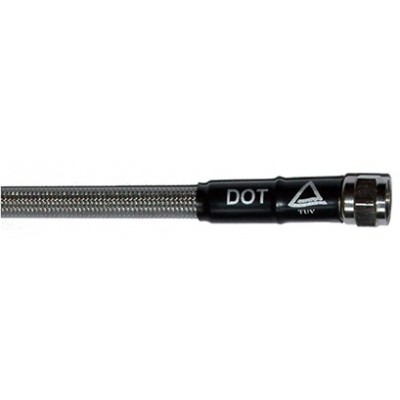

All Powerhose Plus lines are factory made, tested and approved by TUV and DOT. Lines use the highest quality Teflon tube with Stainless steel over braid. The lines are covered in clear PVC as standard. The Powerhose Plus fittings simply screw on to the lines stainless steel 1/8 BSP swivel nuts. This gives perfect alignment.

Brake Hose 1300mm

All Powerhose Plus lines are factory made, tested and approved by TUV and DOT. Lines use the highest quality Teflon tube with Stainless steel over braid. The lines are covered in clear PVC as standard. The Powerhose Plus fittings simply screw on to the lines stainless steel 1/8 BSP swivel nuts. This gives perfect alignment.

1. Hose Measurement

Measure existing line from the centre of the banjo at each end, or as the diagrams below, then subtract 40mm from the overall length. This gives you the line length you will need. If the hose is still fitted to the machine this measurement can be obtained with the careful use of some flexible tubing, following the routing of the old hose exactly.

IMPORTANT: Do not use a hose with a shorter measurement than the original.

2. Select Lines and Identify Fittings

Round up your measurements taken at step 1 to match one of the Hose Lengths available to order online.

Next step is to identify the brake line fittings. Select the closest match banjo angle to the originals. Adapters come in concave and convex variations.

For Banjo Bolts , the following table will help you to identify thread sizes for Banjo bolts and adapters:

|

Suzuki and most European machines |

M10x1mm fine and/or M10x1.25mm course thread |

|

Honda, Yamaha, Kawasaki and Triumph Stock |

M10x1.25mm |

|

Early Triumph and Norton |

3/8 UNF |

|

Harley Davidson |

7/16 24TPI and/or 3/8 UNF |

|

BMW, Brembo & Magura |

M10x1mm |

|

Nissin Calipers |

M10x1.25mm |

Remember to replace copper crush washers where used. You'll need 2 for each single bolt and 3 or 4 for double bolts.

3. Fitting Instructions

To fit Powerhose Plus you will need an 11mm spanner together with a 6mm allen key / hex wrench for any banjo bolts.

Please adhere to the following:

- Double check thread compatibility for master cylinder and calipers.

- Loosely assemble hoses to end fittings and attach to the machine. Remember to renew all copper washers where used.

- Ensure that hoses are correctly routed – use the same routing as manufacturers’ original, unless Race kit used.

- Tighten all swivel nut connections, just over finger tight. Tightening torque 12 NM

- Check operation of forks / suspension arm to ensure that brake lines do not become trapped or stressed, also check steering lock to lock to ensure hoses have enough freeplay.

- Tighten the banjo bolts to the recommended torque setting. (see below)

- Bleed system in accordance with manufacturer’s instructions. We sell a Vacuum Pump if needed.

- Check all joins for leakage under pressure (operate brake lever and pressurise the system).

- Test the operation of the brakes in a safe environment before use and inspect regularly.

The recommended torque settings for 10mm and 3/8th banjo bolts are as follows:

Min 14ft/lbs Max 18 ft/lbs

Min 2 Kilogram-Meter Max 2.5 Kilogram Meter

Min 19 NM Max 25 NM

Powerhose Plus Swivel nut fittings - 12 NM

The torque settings for 5/16th BSF (British Standard Fine) banjo bolts are as follows:

15 ft/lbs or 20 Meter-Newtons